RESEARCH

Application of Nano Silica Sol in Integrated Circuit Processing

2023-03-28 16:21

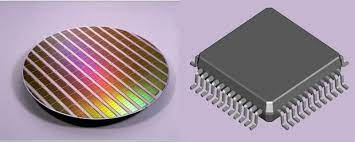

The rapid development direction of the advanced integrated circuit manufacturing industry is high precision, high performance, and high integration, which puts forward high requirements for both local and overall flatness of the wafer surface. At present, ultra precision chemical mechanical polishing (CMP) technology is a surface finishing technology that can provide local and overall flatness of wafers. CMP is mainly based on chemical polishing machines, integrating online monitoring, endpoint detection, cleaning, drying and other technologies. It is a product of the development of integrated circuits towards micro refinement, multi-layer, thinness, and flatness processes.

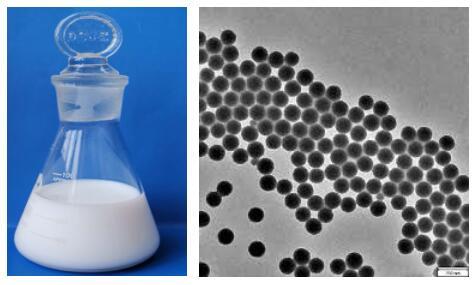

In CMP polishing, commonly used abrasives mainly include nano silica, cerium dioxide, and alumina. The advantages of cerium dioxide abrasive are fast polishing speed, low hardness and good stability. However, the cerium dioxide currently used is basically mechanically grinded, which has defects such as large particle Dispersity, high viscosity, low purity, and high price; Aluminum oxide abrasives have a high hardness and are prone to scratches when polishing soft workpieces, making them less suitable for polishing softer workpieces; The nano silica sol abrasive has a particle size of 1-100nm, which has a large specific surface area, high dispersibility and permeability. Its hardness is relatively soft, and it has minimal damage to the surface of the workpiece. Therefore, it is widely used for polishing the surface of precision optical devices such as wafers and sapphires.