RESEARCH

Application of silica sol in geotechnical engineering

2023-03-29 10:21

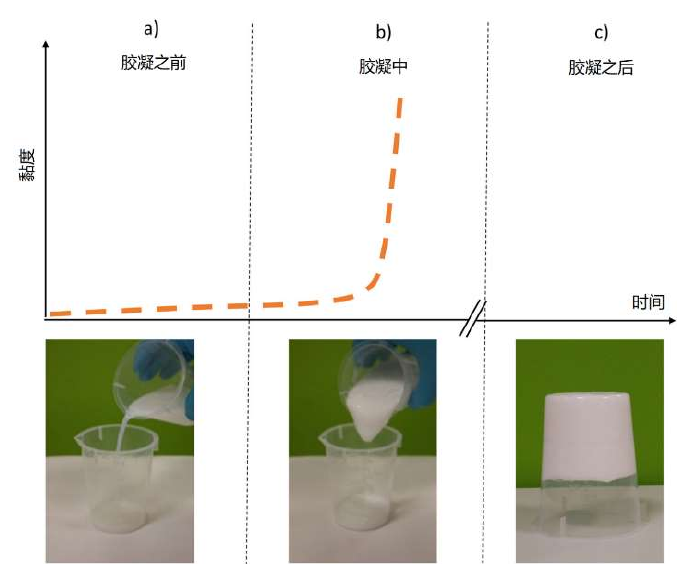

In the process of manufacturing silica sol, an alkaline solution is generally used to maintain a stable liquid state. The alkaline solution makes the silica particles repel each other by ionizing the nanoparticles, so that the silica sol does not undergo gel. By adding electrolyte into the silica sol, the repulsive force between silica particles can be weakened to form a coherent siloxane bond (Si-O-Si) network, so that the silica sol can be gel and the liquid can be transformed into a gel like solid. In the process of gel, the viscosity of silica sol will not increase too much for a period of time, but after a certain time, its viscosity will increase rapidly in a very short time and produce cementation. gel is a solid, as shown in the figure. Based on the gel characteristics of other chemical materials, the gel process of silica sol is divided into three stages. In stage 1, the viscosity of silica sol is similar to that of water, and no gel is formed. In stage 2, the silica sol remains a relatively low viscosity liquid, but after a certain moment, the viscosity will rapidly increase in a short period of time. The whole colloidal slurry will gradually become viscous and difficult to flow, until it becomes a jelly that cannot flow. At this time, the gel has a certain elasticity and plasticity. When reaching stage 3, the gel of silica sol will develop a certain rigidity and become a hard solid.

Therefore, in the engineering research, the liquid silica sol is injected into the foundation by grouting method and other methods, taking advantage of the characteristics of the time-delay growth of the viscosity of silica sol. After waiting for its gel, the loose soil particles are bonded together by cementation, thus completing the reinforcement of the foundation soil.

The gel of silica sol is the key to control the grouting reinforcement effect. Generally, the gel time of the silica sol can be defined as the time between mixing the slurry and forming a firm gel. The gel of silica sol depends on the interaction between particles. The formation time of gel is mainly affected by the content of silica in slurry, the size of silica particles, pH value, ionic strength, solution temperature and other factors.

In general, the higher the concentration of silica in the slurry, the larger the size of silica particles, the greater the ionic degree of the added solution, and the shorter the gel time.