NEWS

Warmly celebrate the successful groundbreaking ceremony of the construction project of a new CMP grinding fluid factory for Shandong Ante nanomaterials with an annual output of 25000 tons of single crystal chips

Published:

2021-12-22 14:41

On the morning of September 29, 2021, the groundbreaking ceremony for the construction project of a new factory area with an annual production capacity of 25000 tons of single crystal chip CMP grinding fluid by Shandong Ante Nano Materials Co., Ltd. was held. Zhang Dianhu, Secretary of the Junan County Party Committee, Hou Zhanfu, County Mayor, Li Chunguang, General Manager of Shandong Ante Nano Materials Co., Ltd., and heads of various departments of the company attended the event.

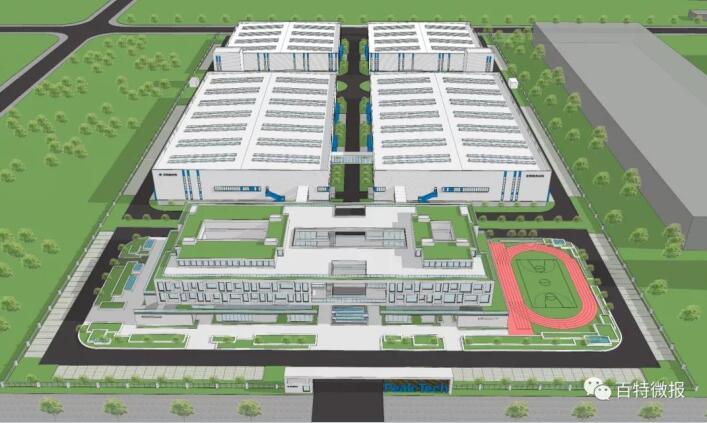

The project covers an area of 100 acres with an investment of 250 million yuan. After the project is completed, it will become an integrated industrial base for joint cooperation in product production, business office, scientific research office, and logistics services.

Finally, in a peaceful atmosphere, everyone lifted the golden shovel and raised the soil to cultivate the foundation.

The successful groundbreaking ceremony marks the official start of the new factory construction project, which focuses on the research and production of chip CMP grinding fluid raw materials. Shandong Baite New Materials Co., Ltd. focuses on the research and development and production of inorganic nanomaterials. In recent years, it has focused on the deep research and development of high-purity nano silica, mastered core technologies, achieved localization, and broken the monopoly of foreign materials and technologies. The project is expected to be completed and put into production by December 2022, with an annual output of 25000 tons of chip CMP grinding fluid, a production value of 300 million yuan, and profits and taxes of 50 million yuan. The implementation of this project is of great significance, It can solve the problem of key raw materials for chips in China relying on imports and being "stuck", and contribute to the realization of chip manufacturing autonomy in China.

Related news

On the morning of September 29, 2021, the groundbreaking ceremony for the construction project of a new factory area with an annual production capacity of 25000 tons of single crystal chip CMP grinding fluid by Shandong Ante Nano Materials Co., Ltd. was held.

The Environmental impact statement and public participation statement of the 15000 ton CMP grinding fluid project of Shandong Baite New Material Co., Ltd. have been prepared. It is proposed to submit the Environmental impact statement of the project to the approval department.

The preparation of the Environmental impact statement of the 15000 ton/year CMP grinding fluid project of Shandong Baite New Materials Co., Ltd. has been officially started. Our company has entrusted the Environmental impact statement preparation unit of the project to carry out environmental assessment.

Silica sol: What are the key points for using silica sol

Silicasol is the aqueous dispersion of nano silica, and nano particles have huge specific surface area, which can produce good adsorption. This time, Baite New Materials will introduce the key points for using silica sol.

Why does silica sol have storage stability?

Silicasol is the dispersion of nano silica, and the particle size of nano particles is generally 3-150nm. The density of nano silica in silica sol is 2.2-2.3, while the density of water is 1, with a significant difference in density. However, we observed that silica sol can maintain suspension stability for a long time. Why is this?

Precautions for the use of silica sol

Although silica sol can maintain suspension stability for a long time, some precautions should be taken during storage, otherwise irreversible damage may occur.

Structure and stability of silica sol

Silica sol is a dispersion of nano silica particles in water or solvent. Silica sol is widely used in CMP polishing fluids, special coatings, papermaking, textiles, precision casting, refractory materials, catalyst carriers, precision ceramics and other fields.