NEWS

Structure and stability of silica sol

Published:

2020-08-10 15:16

Silica sol is a dispersion of nano silica particles in water or solvent. Silica sol is widely used in CMP polishing fluids, special coatings, papermaking, textiles, precision casting, refractory materials, catalyst carriers, precision ceramics and other fields.

Silica sol is a thermodynamic unstable system with huge surface free energy (such as a silica sol with a particle size of 10nm with a specific surface area of 270m2/g). The silica sol system contains a large number of hydrated ions, so particles tend to aggregate with each other to reduce surface energy. Therefore, silica sol stored for a long time may become gel.

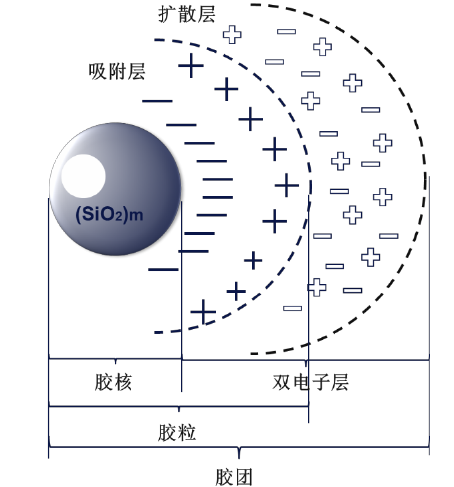

The reason why silica sol can remain stable for a period of time is due to its double layer structure. The structure of silica sol particles is shown in the following figure.

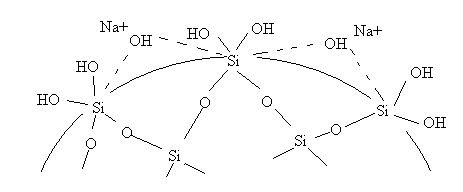

The silica sol particles contain a large amount of siloxane bonds (Si O-Si -) inside, which is an amorphous silica structure; The surface of silica sol particles is covered with silicon hydroxyl groups (Si OH), which form a diffusion double electron layer together with alkali metal ions such as sodium ions and potassium ions. Electrostatic repulsion occurs between particles due to the same charge, which is a key factor for the stable existence of silica sol. In addition, external Brownian motion and solvent barrier are also factors that make silica sol stable.

There are many factors that affect the stability of silica sol, including electrolyte, temperature, concentration, and particle size. The smaller the particle size and larger the specific surface area of silica sol, the greater its surface energy and lower its stability. Once the silica sol forms a gel, it cannot be reduced by heating or adding solvent, so the formation of gel from silica sol is irreversible.

Next

Next

Related news

On the morning of September 29, 2021, the groundbreaking ceremony for the construction project of a new factory area with an annual production capacity of 25000 tons of single crystal chip CMP grinding fluid by Shandong Ante Nano Materials Co., Ltd. was held.

The Environmental impact statement and public participation statement of the 15000 ton CMP grinding fluid project of Shandong Baite New Material Co., Ltd. have been prepared. It is proposed to submit the Environmental impact statement of the project to the approval department.

The preparation of the Environmental impact statement of the 15000 ton/year CMP grinding fluid project of Shandong Baite New Materials Co., Ltd. has been officially started. Our company has entrusted the Environmental impact statement preparation unit of the project to carry out environmental assessment.

Silica sol: What are the key points for using silica sol

Silicasol is the aqueous dispersion of nano silica, and nano particles have huge specific surface area, which can produce good adsorption. This time, Baite New Materials will introduce the key points for using silica sol.

Why does silica sol have storage stability?

Silicasol is the dispersion of nano silica, and the particle size of nano particles is generally 3-150nm. The density of nano silica in silica sol is 2.2-2.3, while the density of water is 1, with a significant difference in density. However, we observed that silica sol can maintain suspension stability for a long time. Why is this?

Precautions for the use of silica sol

Although silica sol can maintain suspension stability for a long time, some precautions should be taken during storage, otherwise irreversible damage may occur.

Structure and stability of silica sol

Silica sol is a dispersion of nano silica particles in water or solvent. Silica sol is widely used in CMP polishing fluids, special coatings, papermaking, textiles, precision casting, refractory materials, catalyst carriers, precision ceramics and other fields.